The history of our density cubes

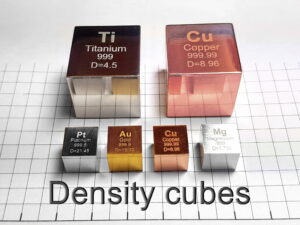

When we crafted our first density cubes for calibration purposes on behalf of a university back in 2009, little did we anticipate the significant impact this product would have, now becoming a staple in every collection of elements. The research requirements were crystal clear: utmost precision, the purest materials, the highest possible material density, and a robust finish, regardless of the cost.

Naturally, we understood that such a product would hardly be of interest to the market or even hardcore collectors due to its exorbitant price. Each cube had to be meticulously calibrated to exact measurements and weight, a process that consumed hours of painstaking work. Even the raw cubes had to be cut with precision, accurate down to 0.02mm through wire erosion, leading to a per-unit cost exceeding 1000 Euros, excluding materials. Only through collaboration with a German company, the creation of custom grinding and polishing equipment, and the development of our engraving laser, did the product become ready for the market. Since then, we’ve counted thousands of collectors and hundreds of schools among our customers for density cubes, and these cubes have been the talk of the town.

However, a significant downturn began around 2016 when Asian sellers flooded various platforms with metal cubes, some priced lower than the cost of a single cut via wire erosion. It became apparent to us that these cubes were designed completely differently, with no regard for quality, where only mass production and price determined the product. Undoubtedly, this was a boon for many collectors, as they could purchase an entire set instead of a single cube. We, too, couldn’t resist and bought cubes of various materials. Yet, we quickly realized they weren’t even suitable as raw materials for further processing, as their tolerances could go up to +- 2mm, making post-processing and grinding far too time-consuming. We had to grasp that these cubes were never intended or suitable as density standards; they were simply basic, cost-effective element samples in cube form.

Ultimately, it’s up to the customer to decide what they want in the end, and it all comes down to the details, much like many other things. In the end, inexpensive mass-produced goods have found their place in every industry, and you can buy a deceptively genuine-looking Gucci handbag for a few Euros in nearly any vacation spot worldwide. Even luxury brands benefit from this, as it increases the recognition of their products and widens their customer base.